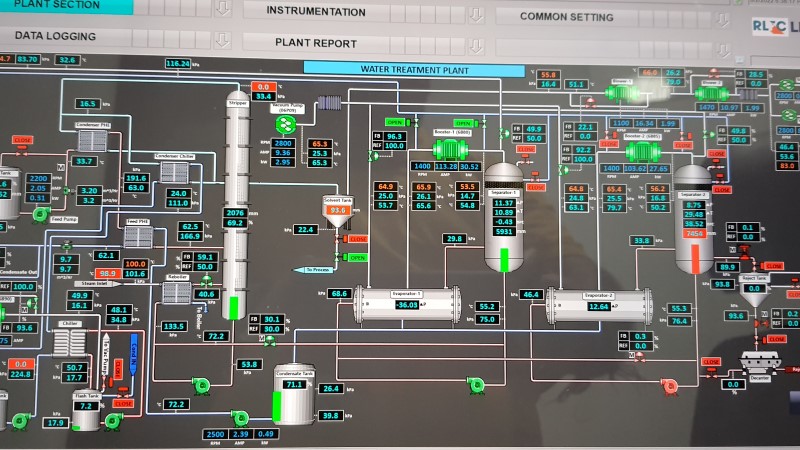

MVR Evaporator (ZLD System)

Solution for concentration of process stream to recover water or dissolved solids.

Vapour recompression is being used in many industrial applications as an alternative to direct steam consumption generated by burning fuel in boiler. Dairy, saline, pharma, other food and distillery industries are among that is using Mechanical Vapour Recompression, in particular, in industrial evaporators for concentration of solids. Waste heat from a spent vapour stream is upgraded to a higher pressure and then re-using it to capture its’ useful energy by simultaneously condensation and evaporation. The vapours generated from evaporator steam is compressed to increase pressure and corresponding temperature. As the pressure rises, the saturation temperature also increases along with some degree of superheat is added to compressed vapours. This increase in saturated temperature generates a temperature difference between the exhaust vapours and the working fluid. The temperature difference then enables heat transfer between the two fluid streams using a heat exchanger element. This arrangement usually employs a compressor to increase the pressure of the vapours stream carrying waste heat. Since energy of latent heat is always reused, the energy input needed for such a process is simply the energy supplied to compress the fluid. This process is very energy-efficient and offers many unique advantages.

This facility is processing effluent of COD 100000ppm & TDS 100000ppm to delivery condensate of less than 350ppm TDS & 90% COD removal using 30kW/m3 power (maximum)

- Client. R L FINE CHEM PVT. LTDAwesome Company

- Location. Plot No 165-182, APIIC Industrial Estate, Thumukunta, Hindupur, Andhrapradesh-515211

- Capacity. 120 KLD

- Year. 2021

- Special Feature ZLD & stripping

- OPEX <30kW/m3