LEPL provides both Reboiled-Stripping and Steam-Stripping systems for removal/separation of solvents. Both kind of stripper comes with provision of reflux and overhead condenser. This is suitable arrangement for removal of NH3, phenol, methanol, ethanol, HCN and low boil solvents present in the feed. In general, stripping is an adiabatic countercurrent cascade flow of vapours and liquid in a column, where components in the entering vapor is tends to be absorbed and components in the entering liquid is tends to be stripped. Effluent have multi components and rigorous solution of equilibrium stages is required. LEPL collects all the relevant feed data for accuracy of the design we provide. We use packed rather than tray-type columns for higher efficiency of random/structured packing with low pressure drop and capacity flexibility. The choice of packed column is based mainly on economics with factors of contacting efficiency, load ability, and pressure drop.

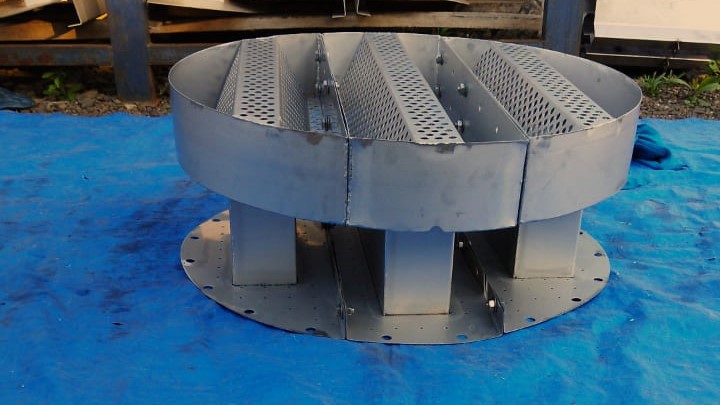

- Carefully designed distributors for initial distribution of liquid across the column cross section and redistributors of liquid

- Option for both random & structured packing.

- Stainless Steel 304/304L, 316/316L, Carbon Steel, Ti.

The removal of substances having reasonable equilibrium vapor pressures at ambient temperatures, including ammonia, and many volatile organic compounds (VOCs), steam-stripping has proven to be efficient way.